Story

The story behind the new product ANTI-BACT

>> Question for Tim Zaiser: How did you come to develop an antibacterial membrane? <<

I can still remember it very well: It was mid-2017 when I met with the CEO of a large laundry chain at the Clean Show in Las Vegas. We were sitting in one of the trade show typical rooms at our booth and had a more or less trade show typical conversation. We talked about the planning for the next year and discussed intensively the advantages of our EASYFIX membrane, which was relatively new at that time, and a great time saver during installation. At the end of the conversation - we were already saying goodbye - my interlocutor described to me that he always had to remove "slime" or an organic layer and germs contained in it on the membrane, especially during maintenance of the extraction membranes - for the cleanliness requirements. This can be a very complex operation. Apart from the expensive downtime, there is also the difficulty of access to the presses themselves in order to clean the membranes properly.

This conversation raised the question of a better, more workable solution.

Immediately after this fair we started to develop the first ideas for an antibacterial membrane, went into testing, developed more ideas and tested again and again until we had a really good result, ANTI-BACT for our EASYFIX membranes. Our new ANTI-BACT membranes enable active germ reduction, which has also been confirmed by the German Hohenstein Institute. This effect exists without quality losses during the complete membrane life and we guarantee this for at least 30,000 press cycles. For our customers, this significantly reduces the effort involved in maintaining the extraction press and the membranes. This is particularly interesting with regard to quality marks or seals for nursing home and hospital linen. For these two target groups or their suppliers, we see ANTI-BACT as an absolute must have.

The Membrane

The combination of EASYFIX and ANTI-BACT significantly reduces possible downtimes of the presses.

MAXI-PRESS presents the world’s first antibacterial membrane for all common water extraction presses in laundries. MAXI-PRESS developed the new “ANTI-BACT” membranes to permanently reduce the risk of bacterial contamination in laundries. The ANTI-BACT products are made of an antibacterial material – tested by the German Hohenstein Institute – which actively prevents the formation of bacteria on the membrane surface.

MAXI-PRESS is a specialist and world market leader in the manufacture of membranes for extraction presses from a wide range of manufacturers. The high-tech products ensure the right level of residual moisture and help to effectively save resources and costs in laundry operations.

Mode of action

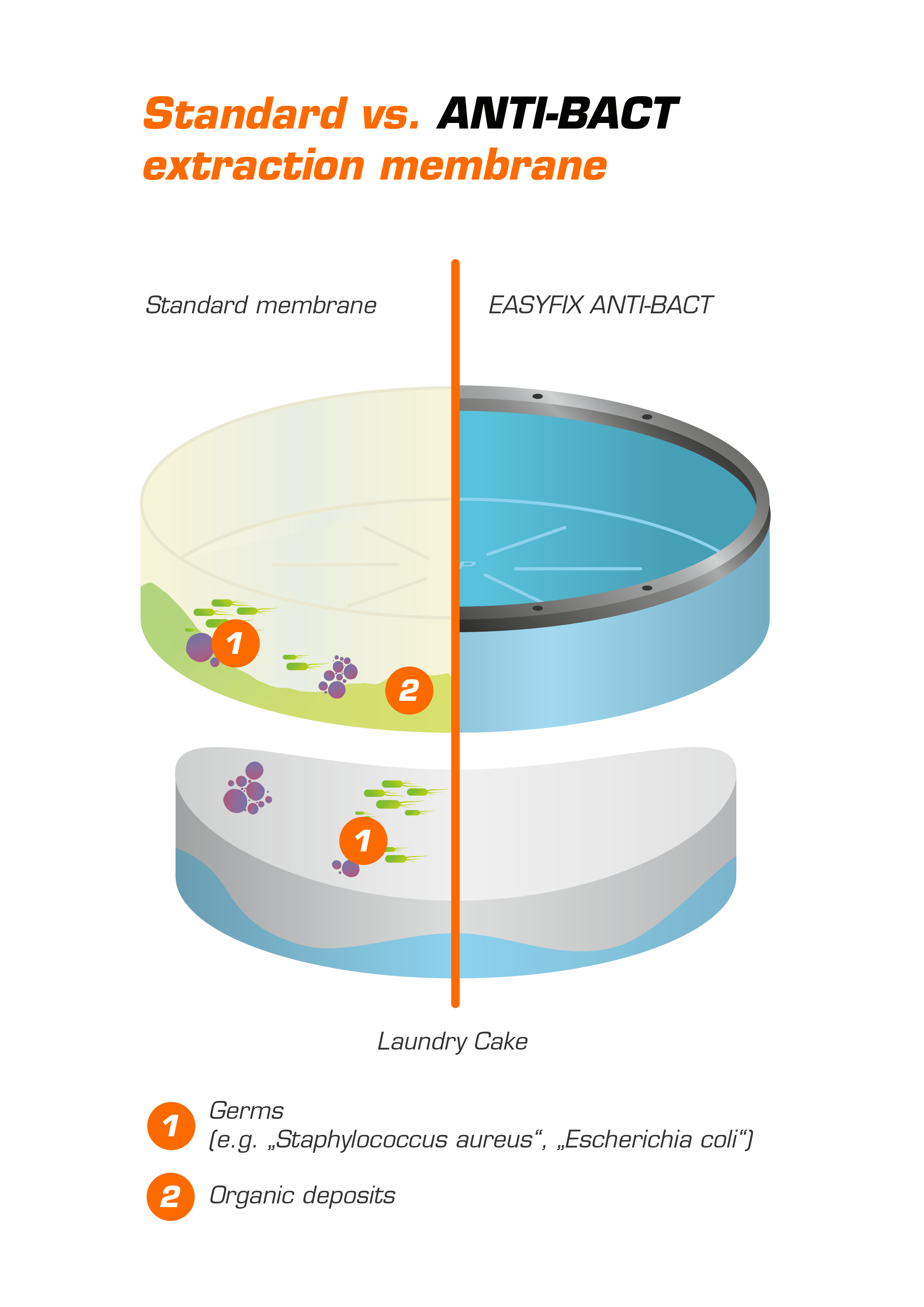

Germs have no chance to develop on the surface of the ANTI-BACT membrane.

To permanently reduce the risk of germ contamination in laundries and to actively prevent the formation of organic deposits on the membrane, we have further developed our tried-and-tested rubber compounds. By adding certain substances to our existing rubber compounds, the surface of the membranes becomes germ-free. We have already been able to solve many of the problems that customers have reported to us in the field of maintenance with our ANTI-BACT rubber compound.

The antibacterial effect of the new ANTI-BACT membranes is unlimited and to make life even easier, the ANTI-BACT is available in the EASYFIX membrane design with built in fixing ring for all common water extraction presses.

Certification

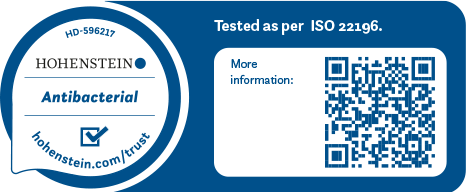

Hohenstein - Textile competence in a nutshell

The German Hohenstein Test Institute has confirmed the sterility of the ANTI-BACT membrane with its test seal. After extensive testing, the product was certified with the “Hohenstein Quality Label – Antibacterial”. The tests were carried out in accordance with recognized standards, for which accreditation is available from the Deutsche Akkreditierungsstelle GmbH. The test basic was to ISO 22196:2011-08 standards (Plastics – Measurement of antibacterial activity on plastic surfaces) with the test germs “Staphylococcus aureus” and “Escherichia coli”.

Register nowTarget groups

Not just for laundries that supply hospitals and care facilities.

Especially significant for laundries that offer textile service to strict standards, for example the German RAL Quality Mark for hospitals and care facilities.

The Maxi-Press membranes are suitable for use in extraction presses from Kannegiesser, Jensen, Passat, Lavatec and many other manufacturers.

EASYFIX

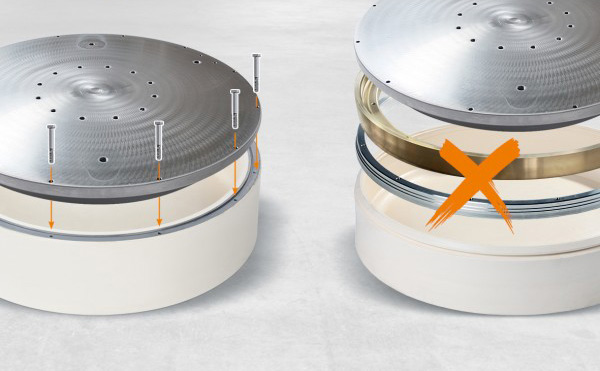

The fastening ring incorporated into the membrane significantly reduces assembly time.

The additional function ANTI-BACT is available for all common extraction presses with EASYFIX membranes. The ANTI-BACT products combine the new germ-reducing properties with all the known advantages of the previous EASYFIX membranes from MAXI-PRESS and are given the suffix "AB".

EASYFIX are membranes with an integrated fastening ring. The EASYFIX membranes from MAXI-PRESS can be replaced much more easily and quickly - without additional fastening rings - than standard membranes.

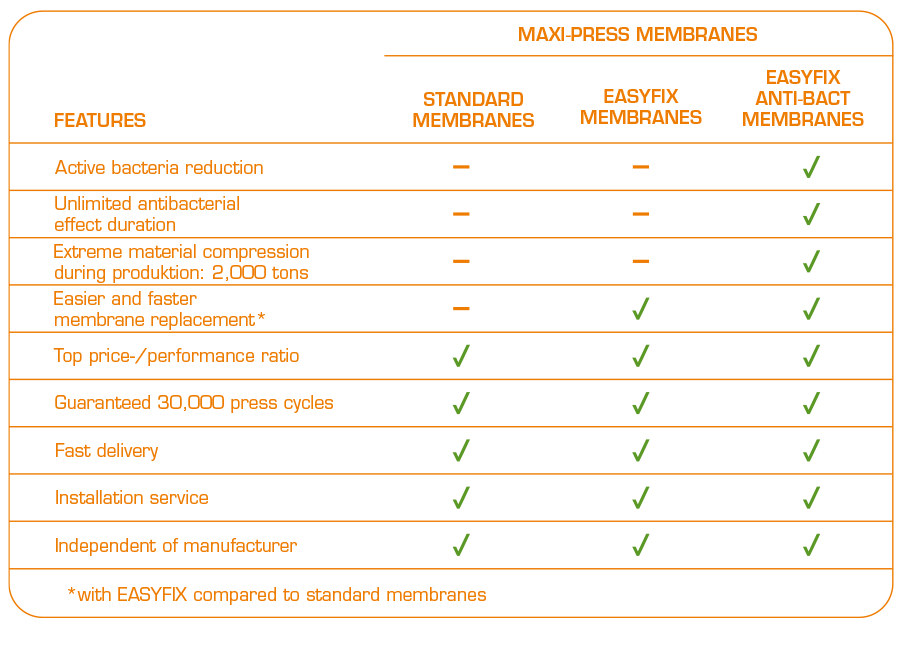

Comparison of the MAXI-PRESS membranes EASYFIX and their ANTI-BACT variant EASYFIX AB

EASYFIX membranes have a fastening ring firmly integrated into the membrane. This eliminates the need for separate fastening rings, which shortens the installation time by saving an entire work step. Our customers also particularly appreciate the high-quality material and the long service life of EASYFIX membranes.

Thus, the press cycles of an EASYFIX extraction membrane clearly exceed the press cycles of conventional membranes from other manufacturers. For this reason, we offer our customers a guarantee of at least 30,000 press cycles with one membrane. MAXI-PRESS produces all membranes from specially developed rubber compounds that meet the highest demands.

Production plant

MAXI-PRESS compresses the special material for the antibacterial membranes with a pressure of 2,000 tons.

The production of ANTI-BACT membranes takes place directly in our production plant in Eichenzell near Fulda with a new production line commissioned especially for this product series. In order to be able to implement this product revolution, MAXI-PRESS has invested around 1 million euros in its own machinery.

There, MAXI-PRESS compresses the special material for the antibacterial membranes with a pressure of 20,000 kilo-Newtons. Only these extreme forces make it possible to produce membranes with an increased rubber content. This enormous pressure from the press ensures maximum compaction of the product, thereby increasing the service life, elasticity and stability of the rubber. The best prerequisite for the production of ANTI-BACT membranes.

The WKP 20000 S press from Wickert was developed together with MAXI-PRESS. The highest premise for the project was quality and reliability; all important components are Made in Germany. The machine uses the latest technology in this field, e.g. constant control and visualization of the temperature within the 18 heating circuits is guaranteed. Mixing and weighing according to recipe, pressing, vulcanizing and all other steps are fully automatic.

Register now